How To Install Samsung Dryer Heating Element DC97-14486A

Samsung dryer heating element DC97-14486A is used on many Samsung clothes dryers and even some Maytag (Neptune) and Amana dryer models. When the heating element goes bad, it will usually have a break in the heating coil which will cause the element not to heat. These instructions work for most Samsung dryers, some may have some small differences but the overall process if very similar. Here is how to replace and test the DC97-14486A & DC47-00019A heating element:

First, unplug or shut off the power to the dryer before working on it.

Then remove the two screws securing the top panel to the back of the dryer. Slide the top panel towards the back of the dryer to remove. Now you will need to remove the front control panel, some model will have screws securing this. Remove them and then pull up to remove, you should have enough extra wire to set the control panel on top of the dryer to get it out of the way (if not, then disconnect the wires and set it off to the side).

Behind where the control panel was there will be four screws that secure the front panel of the dryer to the frame. Remove these four screws.

Open the door of the dryer, there will be two screws that need to be removed at the bottom of the door frame area. With those two screws removed you should be able to tilt the front panel forward, remove the connector to the door switch, and remove the front panel.

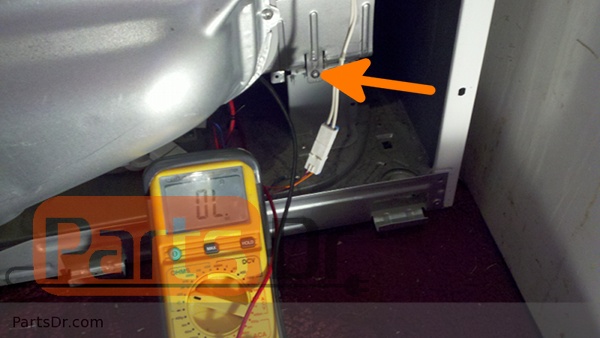

The heating element is located on the bottom right side of the dryer. To remove the element you will need to remove the wires to the heating element, thermal fuse, and thermostat. Then remove the mounting screw in the front and the whole heating element assembly should pull out the front of the dryer.

To test the heating element, you will need an Ohm meter or multi-meter. A good heating element should read approximately 9-10 ohms. A burned out element will have an infinite resistance (it won’t register anything). See the video below for instructions on how to test the heating element.

To re-install the heating element you will need to put everything back in the reverse order. If you lost track of how the wires connect to the heating element, please see the picture below.

If you need to purchase a new Samsung dryer heating element, click one of the two links below.

The best way to purchase the heating element is as an assembly. The heating element assembly includes the heating element, two thermostats, and housing.

Heating Element Assembly – Part # PD00002003 (mfg # DC97-14486A)

We also sell the heating element by itself. You will need to re-use the thermostats and element housing.