How To Test a GE Refrigerator Thermistor Sensor WR55X10025

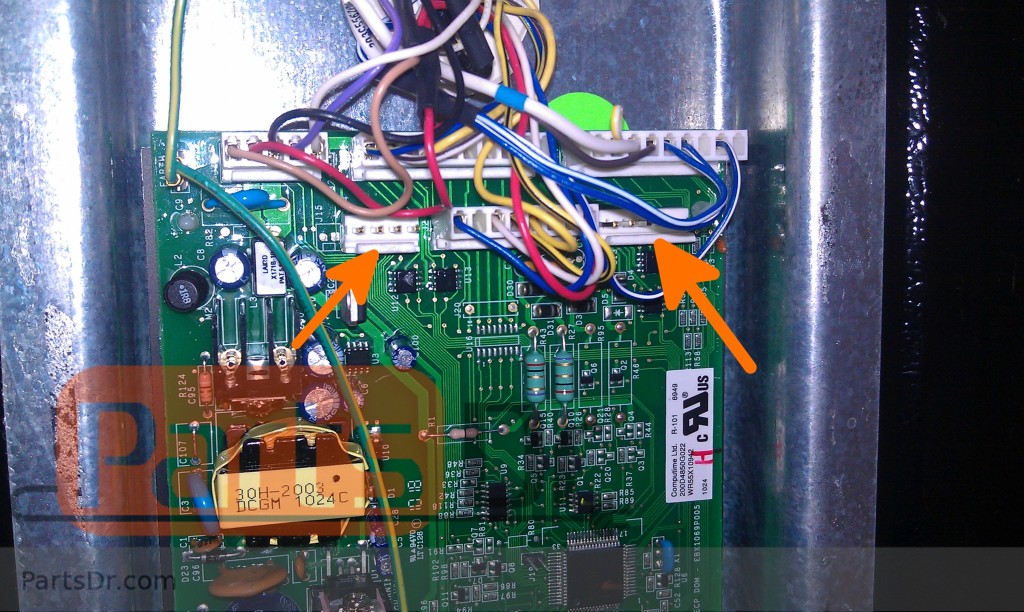

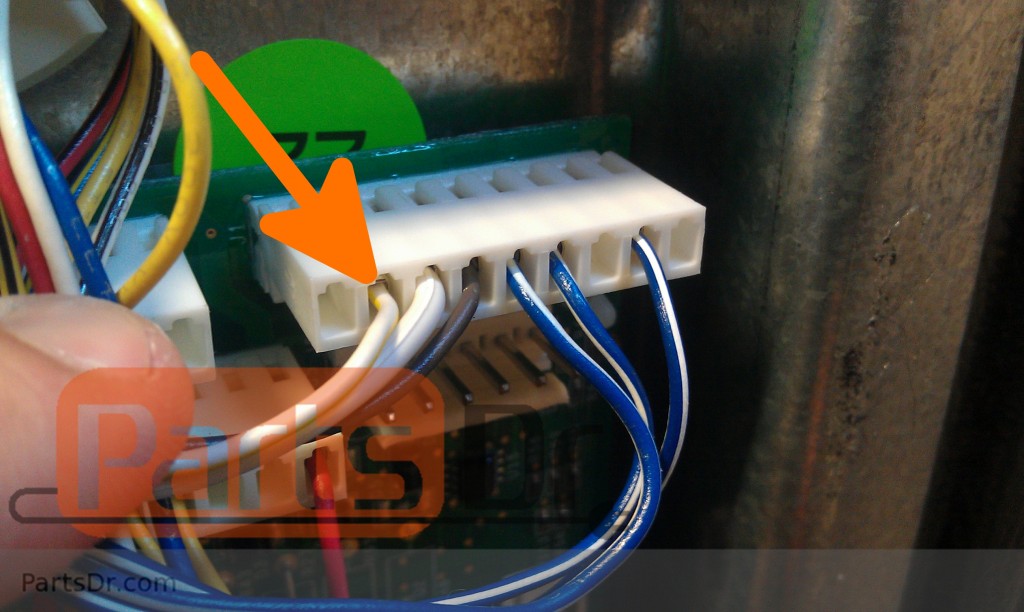

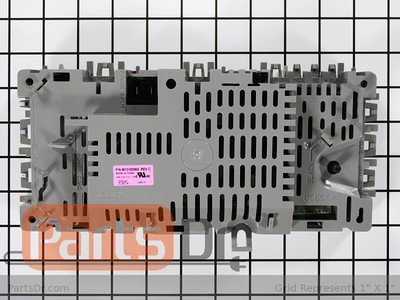

Some newer GE model refrigerators manufactured after 2002 use a thermistor in the refrigerator and freezer sections to control the temperature and the automatic defrost cycle. The thermistor is a variable resistor that varies its resistance depending on the temperature. It is sometimes referred to as a temperature sensor. GE used these thermistors on some Side-by-Side, bottom freezer, and top freezer refrigerator models that use a main control board on the back of the refrigerator. The main control board monitors and reads all of the thermistors to properly control all of the functions of the refrigerator. Please note that all of the thermistors on these models are the same.

**Before working on your refrigerator, make sure the refrigerator is unplugged.**

Thermistor Locations & Functions

Refrigerator Section: The refrigerator may have one or two thermistors located in different areas to monitor the temperature in the refrigerator section. These sensors send their signal to the main control board, which may turn on/off the compressor or evaporator fan motor, or open/close the air damper to let more or less cold air into the refrigerator compartment. When one of these sensors fails, it can cause the temperature to be off or even cause the refrigerator not to run (not very common).

Freezer Section: The freezer section has one thermistor sensor, not including the thermistor on the evaporator coil (see below). This sensor sends its signal to the main control board which may turn the compressor on/off or turn the evaporator fan motor on/off. When this sensor fails, it can cause the temperature to be off or even cause the refrigerator not to run (not very common).

Evaporator Coil: The evaporator coil (located behind the back panel in the freezer section) has one thermistor sensor attached to the top side of the evaporator coil. The control board monitors this thermistor and uses it to know when to go in and out of the automatic defrost cycle. Some people refer to this thermistor as the defrost sensor. This is the most common sensor to fail because it is subject to extreme temperature changes and moisture. When this sensor fails it can cause the refrigerator to not go through the automatic defrost cycle properly. When replacing this sensor, you must first manually defrost the evaporator coil to get it caught back up for the refrigerator to continue to work properly going forward.

Old Style Vs. New Style Thermistor

Some refrigerator manufactured 2005 and earlier may have a thermistor design that is prone to failure. The differences between the old and new style thermistor is easy to spot. The old style thermistor has a black area around where the wires come out of the sensor and it also has a rounded tip. The new style sensor is white around where the wires come out of the sensor and the tip of the sensor is flat. If your refrigerator has the old style thermistor sensors, then you should change out all of the thermistors with the new style sensor.

The old style thermistor is pictured on the left with a round tip and the new style thermistor is pictured on the right with a flat tip.

The old style thermistor is pictured on the left with a round tip and the new style thermistor is pictured on the right with a flat tip.

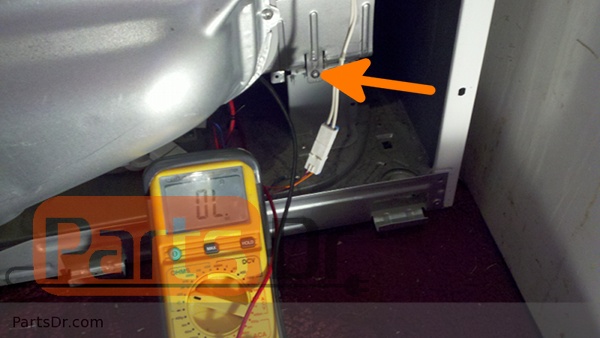

How To Test The Thermistor

You can test your thermistor(s) using an ohm meter or multi-meter. The best way to do this is to remove the thermistor from the refrigerator so you can control the temperature of the sensor. You can let the sensor warm up to room temperature or grab a glass of ice water to test the thermistor. With the sensor warmed up to room temperature the sensor should read approximately 6.2K Ohms at 68°F. With the thermistor submerged is a glass full of ice water, the sensor should be very close to 32°F which should read approximately 16.3K Ohms. If the values that you are getting are far off from these readings, then the sensor is bad and should be replaced. If the reading you are getting is not consistent; where sometimes the ohm reading is correct and other times it isn’t, even though the temperature hasn’t changed, then the thermistor should be replaced.

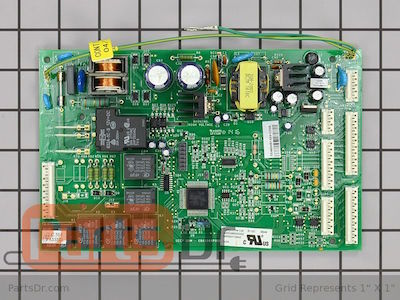

Where to Buy

The common thermistor used on some GE refrigerators is part number WR55X10025. Thermistors are model specific and should be verified with the model number of the refrigerator before ordering. This is the newest version of this part, and has been improved to have less problems. Click the link below to visit our store to purchase a replacement thermistor sensor.