How To Replace 34001320 Neptune Drain Pump

Replacing the 34001320 drain pump on your Maytag Neptune washer is easy to do. This pump is found on many newer Maytag Neptune washing machines. When this pump goes bad or jams up (something gets stuck in the impeller), the washer will display an “ND” (No Drain) error code. Here is on how replace the drain pump:

The drain pump is located in the back of the washer.

First unplug the washer.

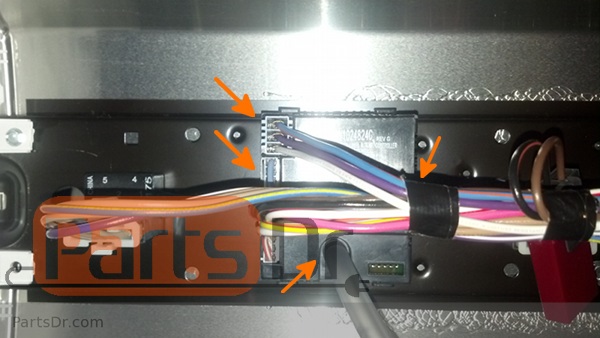

Then remove the two screws holding on the back panel.

Slide the panel up, and then pull out to remove the panel.

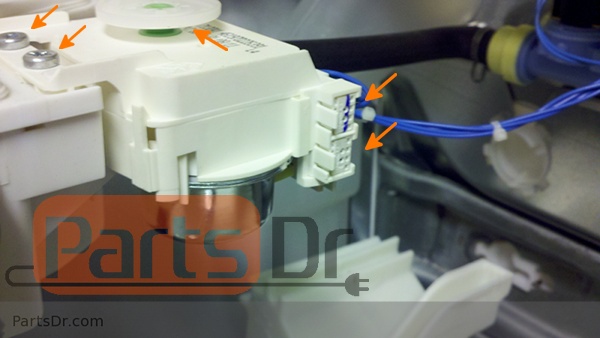

You should now see the pump on the left hand side. Remove the electrical connector (left red arrow).

Before removing the hose clamps, have a wet shop vac ready to suck up the water. I usually try to suck all of the water through the drain hose by putting the hose from the vacuum on the end of the drain hose and sealing the gap with my hand. If that doesn’t work then slowly remove one of the drain hoses and try to suck up all of the water before removing the hose all of the way.

Once all of the water is drained out then removed both hose clamps (middle and right red arrow). You’ll notice the clamps in the picture look different than the clamps that come with the washer. The clamps that come from the factory are weak and often leak, I would recommend upgrading these to worm gear style clamps while you have this apart.

Next remove the three 1/2 inch bolts holding the pump to the base of the washer (3 orange arrows).

With the pump removed look for anything stuck in the pump, and look to see that the three blades on the impeller look good. If the pump is bad, replace the pump.

Reassemble in the reverse order.

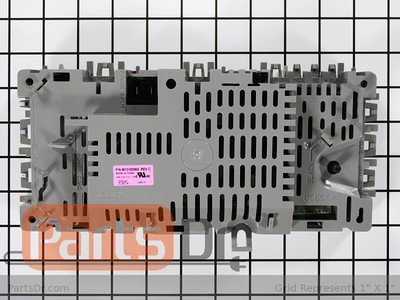

If you have a bad drain pump and need to purchase a new one, please click the link below:

Drain Pump Assembly – 34001320

If part number 34001320 is not available, you can use part number DC96-00774A in its place.