Fixing F4 E3 Dryer Error Code

Introduction:

Is your dryer displaying the F4 E3 error code, leaving you puzzled and disrupting your laundry routine? No need to panic – this common issue with dryers can often be addressed without the need for professional assistance. In this guide, we will walk you through the steps to diagnose and fix the F4 E3 error code, ensuring your dryer gets back to optimal performance.

Understanding the F4 E3 Error Code:

Before we jump into solutions, it’s crucial to understand the meaning behind the F4 E3 error code. In most dryers made by Whirlpool, including Maytag, Amana, Kenmore and more, this code typically points to an airflow restriction issue. This restriction can lead to overheating and potential damage to your dryer.

Diagnosing the Problem:

To troubleshoot the F4 E3 error code, follow these systematic steps:

- Check Home Exhaust Vent: Ensure your home’s ventilation system is free from obstructions. Lint buildup, debris, or even bird nests in the vent can cause airflow restrictions.

- Inspect Vent Hose: Examine the vent hose that connects the dryer’s exhaust vent to the home for any kinks or blockages. A smooth, unrestricted path is crucial for proper airflow.

- Clean Lint Filter: Regularly clean the lint filter, as a clogged filter can impede airflow and trigger the error code.

Fixing the F4 E3 Error Code:

Once you’ve identified the airflow restriction as the likely issue, follow these steps to resolve the F4 E3 error code:

- Safety First: Unplug the dryer from the power source to ensure safety during the repair process.

- Vent Cleaning: Thoroughly clean the entire ventilation system, from the lint filter to the exterior vent. Use a vent cleaning kit or a vacuum with an extended attachment. If you have a long or hard to clean vent, look into hiring a professional to clean it.

- Inspect Vent Hose: Check the vent hose that goes between the dryer and the house exhaust vent for any damage or blockages. Replace if necessary.

- Lint Filter Replacement: If the lint filter is damaged or excessively clogged, consider replacing it with a new one.

- Reassemble and Test: Once the cleaning and replacements are complete, reassemble the dryer, plug it in, and run a test cycle to ensure the F4 E3 error code is resolved.

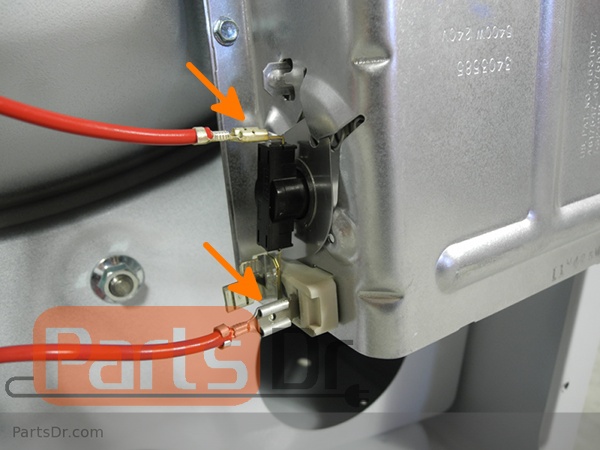

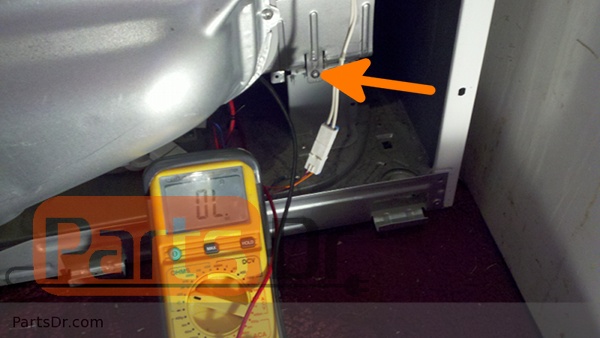

- Dryer not Working: If your dryer no longer works or starts, you may need to replace the thermal fuse, as it may have blown when the dryer was too hot trying to move air through the constricted airways. You can learn how to test your dryer’s thermal fuse here. To find and purchase the correct thermal fuse for your model, use the search box at the top of this page and enter your dryer’s model number to find the correct thermal fuse.

Conclusion:

Don’t let the F4 E3 dryer error code disrupt your laundry routine. By diagnosing the issue and following these steps to address airflow restrictions, you can save time and money on service calls.

We hope this guide has helped you tackle the F4 E3 error code in your dryer. If you have any questions or need further clarification, feel free to ask in the comments section. Don’t forget to search our site for all of your appliance parts that may be needed! Happy drying!